© Mark Aherne 2023 : The Tudors, The Street, Brantham, Essex CO11 1PH : Email : Sales@bespoke-electronics.co.uk UK Company Registration Number : 12556716 : Dissolved 19 October 2021

Weld Monitor Applications - Manual & Automatic

Manual Welding Systems

In Manual spot weld applications, the user simply sets the controls to suit the programmed weld schedule. If you change the schedule, you just change the settings to the pre-determined settings that suit the schedule. Single or double pulse welding, with or without polarity reversal is accommodated.

Automatic Welding Systems

In Automatic applications, the monitor can be used in the same way as for a manual application. Alternatively, the automatic equipment can be configured to measure and react to the optional isolated Peak Energy Output signal that is timed and held in conjunction with the PLC interfacing signals. In this way, the automatic system designer is free to determine their own software based process limits.

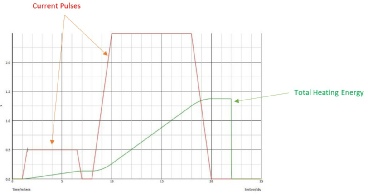

When a weld pulse occurs, a 250mS timing signal is developed and made available at the PLC interface. At the same time, the Peak Electrical Heat Energy Analogue signal is made available at the optional analogue output channel. The automatic system designer simply needs to trigger and operate their data acquisition system via these two signals. Click here for a detailed guide

- The Weld Monitor Unit captures the total electrical heat energy and compares this to the user setting.

- Optionally, these electrical measurements are readily transferred into data acquisition systems.

| Introduction |

| Demo Videos |

| Monitoring Accuracy |

| Taking Measurements |

| Application Notes |

| Overview |

| Manual or Automatic |

| Capacitor Discharge PSUs |

| "Built In" Weld Monitors |

| Closed Loop Welding PSUs |

| Pulsed Micro Arc |

| Process Review |

| Automation |

| Data Acquisition |

| Welding Applications |

| Product Pricing |

| Consultancy |

| History |

| FAQs |

| Contact |