© Bespoke Electronics Limited 2023 : The Tudors, The Street, Brantham, Essex CO11 1PH : Tel : +44 (0) 1473 328695 : Email : sales@weld-monitor.com UK Company Registration Number : 12556716

Can I take measurements with the Weld Monitor Unit ?

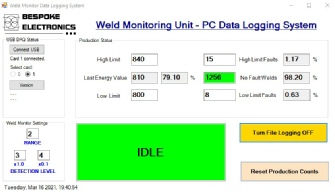

YES.. of course you can. The Weld Monitor Unit can be supplied with Isolated Analogue Outputs which can be used to directly measure the weld heat energy supplied to each weld and then data logged for each and every weld. A simple PC based, USB data logging unit is available as a cost option to accompany the isolated analogue channel option. Weld Data Logging System PDF data sheet

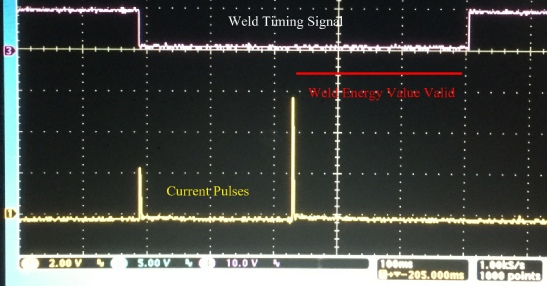

There are two electrical channels, link configurable to measure the real time current or energy waveforms along with the total energy value. The total energy signal is held stable for data acquisition for 250mS post weld allowing very simple and low cost data measurement systems to be used. A standard optically isolated 15 pin D-type digital interface provides logical status, triggering and data capture timing signals, all easily interfaced to Automation PLCs, PC data acquisition systems and other measurement devices.

In addition to PLCs, off the shelf Ethernet, USB and Serial port based RS232/RS485 data logging and acquisition systems are available from multiple sources from as little as £50 to around £200. Standalone LCD graphical PLCs with analogue input channels start at around £80 and provide options for Ethernet etc… these readily facilitate production counts, Good & Bad weld logging etc…

Data logging formats, interfacing and storage preferences differ considerably from user to user, so if you would like a specific data collection solution, then please enquire as we are more than willing and able to provide help and/or tailor user specific solutions as and when required. Click here for a detailed guide to interfacing the weld monitor for automation, data acquisition and logging.

In it’s simplest form, the data collection system can be triggered to take a measurement by the PLC Weld timing interfacing signals or the acquisition system can simple poll the analogue channel and make a recording once a low level threshold is exceeded. e.g. an 8 channel 12 bit USB data collection system can be easily interfaced for around £90 allowing you to capture the entire analogue waveforms if you really want to !!

Google “Low Cost USB data acquisition products” and you should find almost off the shelf hardware solutions or consider.

https://uk.rs-online.com/web/p/plcs-programmable-logic-controllers/1819079/

https://www.omega.co.uk/pptst/D5000.html

https://www.picotech.com/data-logger/picolog-1000-series/multi-channel-daq

https://www.measurementsystems.co.uk/usb-201

Think before you log !! In most applications, if something starts to go wrong, the process stops and corrective actions is taken. Thus in most cases, you simply want to know what has failed and when. It is important to think about what you really need to log since there are many hard drives out there full of waveform data that people simply don’t have the time or inclination to look at. Such mass data collections often detract from any value add in monitoring.

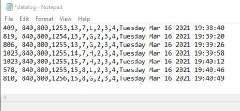

Basic statistics can be useful in analysing the average process norms for weld energy delivered and are readily computed either by a PLC or PC data acquisition system as shown above.

| Introduction |

| Demo Videos |

| Monitoring Accuracy |

| Taking Measurements |

| Application Notes |

| Overview |

| Manual or Automatic |

| Capacitor Discharge PSUs |

| "Built In" Weld Monitors |

| Closed Loop Welding PSUs |

| Pulsed Micro Arc |

| Process Review |

| Automation |

| Data Acquisition |

| Welding Applications |

| Product Pricing |

| Consultancy |

| History |

| FAQs |

| Contact |