© Bespoke Electronics Limited 2023 : The Tudors, The Street, Brantham, Essex CO11 1PH : Tel : +44 (0) 1473 328695 : Email : sales@weld-monitor.com UK Company Registration Number : 12556716

How does the Weld Monitor Unit work ?

The Weld Monitoring Unit combines precision electronics with a novel UK patent pending (GB 2006623.9) technique to measure and monitor the repeatability of a spot welding process.

Put simply, the weld monitor precisely measures and captures the amount of electrical heat energy delivered to a spot welding joint and compares this to a user defined setting. If the heat energy is too high or too low, as set by the user, then the unit indicates this in a number of ways. The unit can be configured to do this using a current sensor measurement only, or using both voltage and current measurements.

The weld monitor unit operates rather like a radio tuned to a favourite station. All the user need do, is perform a few exemplary welds and set the range and level controls accordingly. Thereafter the control settings provide a numeric “program” definition for reference and the monitor remains set at monitoring and expecting repeatable process measurements. If you change your welding program, you simply change the settings.

How accurate is the Weld Monitor Unit ?

Unlike more expensive conventional digital capture based weld monitors, this Weld Monitor Unit makes no attempt to measure or reference S.I. Electrical or Energy Units and hence does not need regular calibration checks or adjustments.

Instead, the unit uses highly stable precision analogue electronics to capture the real time delivered weld energy which is then precisely compared to the user set process value.

This novel, UK patent pending (GB 2006623.9) approach means that very tight process tolerances can be derived and hence very small changes can be detected, as are typical with electrode wear, component misplacement, operator variance etc…

- For a 125W/S Capacitor Discharge Machine, 0.1W/S output changes are readily detected, indicative of a sensitive welding problem

- Operating with a 45 Newton welding force with a cross wire weld, the unit can detect a 3 Newton error in force setting

- Easily detects accidental over welds, accidental component misplacement and missing components

- The unit can be configured to detect electrode wear and be used as an indicator to redress the electrodes

Can I make an electrical measurement with the Weld Monitor Unit ?

YES.. Of course you can. !! As a cost option, the Weld Monitor an be supplied with Isolated Analogue Outputs which can be used to measure an electrical value entirely indicative of the weld heat energy supplied.

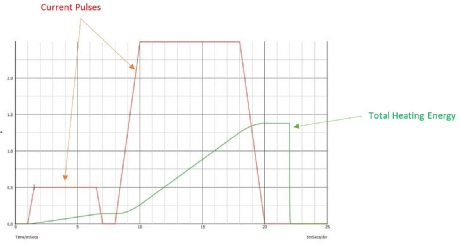

There are two electrical channels, typically configured to measure the real time current waveform and total energy.

The total energy signal is held stable for data acquisition for 250mS allowing very simple data measurement systems to be used.

A standard optically isolated 15 pin D-type digital interface provides timing and status signals that provide status, triggering and data capture timing signals, all easily interfaced to Automation PLCs, PC data acquisition systems and other measurement devices. Click here for more detailed info….

- The Weld Monitor Unit captures the total electrical heat energy and compares this to the user setting.

- Excessive variations in the heating energy are indicative of a process problem or problems and are indicated to the user and/or an automation system on a weld by weld basis.

- Optionally, these electrical measurements are readily transferred into data acquisition systems.

| Introduction |

| Demo Videos |

| Monitoring Accuracy |

| Taking Measurements |

| Application Notes |

| Overview |

| Manual or Automatic |

| Capacitor Discharge PSUs |

| "Built In" Weld Monitors |

| Closed Loop Welding PSUs |

| Pulsed Micro Arc |

| Process Review |

| Automation |

| Data Acquisition |

| Welding Applications |

| Product Pricing |

| Consultancy |

| History |

| FAQs |

| Contact |