© Mark Aherne 2023 : The Tudors, The Street, Brantham, Essex CO11 1PH : Email : Sales@bespoke-electronics.co.uk UK Company Registration Number : 12556716 : Dissolved 19 October 2021

Weld Monitor with Data Acquisition

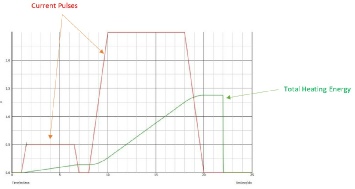

The Weld Monitoring Unit uses real time current and voltage measurement signals to derive a real time measurement value for the delivered heat energy.

The current and total weld energy signals can be made available via isolated analogue channels for the purpose of real time data acquisition. The total energy signal is held stable for up to 250mS after the last weld and is thus readily sampled by Low cost. Low bandwidth analogue to digital sampling systems, such as PLCs and PCs.

Click here for more detailed information...

The standard Weld Monitor is fitted with a 15W D type connector that provides 4 optically isolated digital outputs specifically designed to interface with industrial PLCs.

These timing signals can also be used in conjunction with the optional Isolated Analogue Channel Outputs in order to provide triggering and capture signals for data acquisition purposes. Once configured, such systems can then be programmed to operate automatically over a wide range of welding schedules, effectively ignoring the manual settings on the unit.

All analogue signals are derived from precision referenced electronics designed to remain temperature stable and supply independent and as such can be readily calibrated within the external data acquisition system.

- The Weld Monitoring Unit captures the total electrical heat energy and compares this to the user setting.

- Excessive variations in the heating energy are indicative of a process problem or problems and are indicated to the user and/or an automation system on a weld by weld basis.

| Introduction |

| Demo Videos |

| Monitoring Accuracy |

| Taking Measurements |

| Application Notes |

| Overview |

| Manual or Automatic |

| Capacitor Discharge PSUs |

| "Built In" Weld Monitors |

| Closed Loop Welding PSUs |

| Pulsed Micro Arc |

| Process Review |

| Automation |

| Data Acquisition |

| Welding Applications |

| Product Pricing |

| Consultancy |

| History |

| FAQs |

| Contact |