© Mark Aherne 2023 : The Tudors, The Street, Brantham, Essex CO11 1PH : Email : Sales@bespoke-electronics.co.uk UK Company Registration Number : 12556716 : Dissolved 19 October 2021

Weld Monitor - Introduction

The Weld Monitor combines precision electronics with a novel technique to measure and monitor the repeatability of a spot welding process.

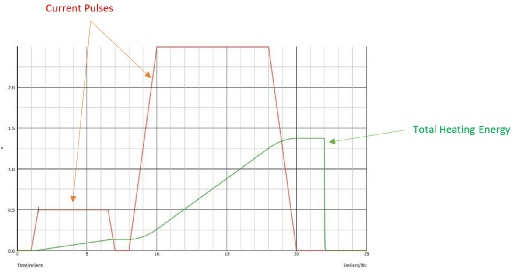

The unit precisely measures and captures the amount of electrical heat energy delivered to a spot welding joint and compares this to a user defined setting. If the heat energy is too high or too low, as set by the user, then the unit indicates this in a number of ways.

The weld monitor can be configured to do this using a current sensor measurement only, or using both voltage and current measurements.

The monitor operates rather like a radio tuned to a favourite station. All the user need do, is perform a few exemplary welds and set the range and level controls accordingly. Thereafter the control settings provide a numeric “program” definition for reference and the monitor remains set at monitoring and expecting repeatable process measurements. If you change your welding program, you simply change the settings.

- The Weld Monitor Unit captures the total electrical heat energy and compares this to the user setting.

- Excessive variations in the heating energy are indicative of a process problem or problems and are indicated to the user and/or an automation system on a weld by weld basis.

- Optionally, these electrical measurements are readily transferred into data acquisition systems.

| Introduction |

| Demo Videos |

| Monitoring Accuracy |

| Taking Measurements |

| Application Notes |

| Overview |

| Manual or Automatic |

| Capacitor Discharge PSUs |

| "Built In" Weld Monitors |

| Closed Loop Welding PSUs |

| Pulsed Micro Arc |

| Process Review |

| Automation |

| Data Acquisition |

| Welding Applications |

| Product Pricing |

| Consultancy |

| History |

| FAQs |

| Contact |